- Home

- About TBT

- Products

- Material

- Cement

- Concrete

- Asphalt-bitumen

- Soil

- In-Situ Testing

- Tri-axial Test Apparatus

- Consolidation Testing Machine/Consolidometer

- Shear Testing Apparatus/Machine

- Compaction Test Machine/Compactor

- Permeation/Swell Testing Apparatus/Permeameter

- Density Testing Machine/Apparatus

- Soil Moisture Meter

- Atterberg limits / liquid plastic limit

- Other Equipment/Machine

- Geotextile & Geosynthetics

- Pavement

- Rock

- Aggregate

- Geological

- NDT

- Petroleum

- Ceramic

- General Lab

- PH Meter

- Conductivity Meter

- Biochemical Analyzer

- Centrifuge

- Furnace/Drying Oven

- Electric Balance

- Thermometer/Hygrometer

- Microscope

- Whiteness Tester/Color Meter

- Ball Mill

- Vacuum Pump

- Magnetic Stirrer

- Refractometer

- Indicator Paper

- Supersonic Cleaner

- Water Bath

- Spectrophotometer(UV/VIS/AAS)

- Viscometer

- Cuvette

- Environment Meter

- Other Equipments

- Color Meter / Gloss Meter

- Rubber-Plastic

- Surveying

- Paint

- News & Events

- Download

- Contact us

Efficient Asphalt Compaction:The Gyratory Compactor in Road Construction

Road construction is a complex process that requires meticulous planning and execution to ensure durability and longevity of the infrastructure.One crucial aspect of road construction is asphalt compaction, which involves the dense packing of asphalt materials to create a smooth and sturdy surface. In recent years, the gyratory compactor has emerged as a game-changer in the field of road construction.

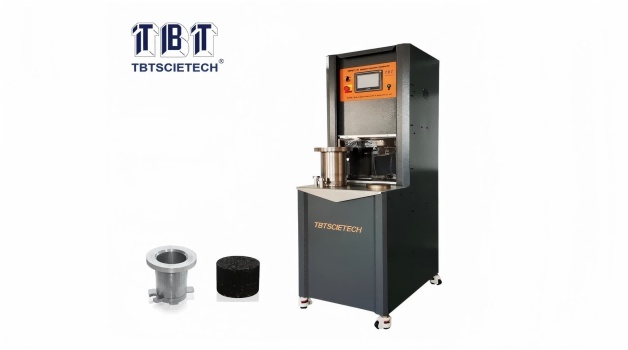

Gyratory Compactor is a specialized machine that utilizes a unique compaction method to achieve highly efficient and effective compaction of asphalt materials. This article explores the benefits of using the Gyratory Compactor TBTXY-170 in road construction, as well as the proper operation and maintenance of this innovative machine.

Benefits of Using the Gyratory Compactor

The Gyratory Compactor has revolutionized the process of road construction and has become an indispensable tool for civil engineers and contractors. This innovative machine offers a plethora of benefits that enhance the efficiency and durability of roadways.

One of the primary advantages of using the Gyratory Compactor is its ability to produce asphalt mixtures with superior compaction qualities. The compactor utilizes a unique gyratory motion that simulates the compaction forces experienced by asphalt pavements under actual traffic conditions. This ensures that the asphalt mixture is compacted uniformly, resulting in a dense and robust pavement structure. The compactor's gyratory motion also helps in eliminating any air voids or weak spots in the pavement, ensuring that the road surface is smooth and durable.

Another significant benefit of the Gyratory Compactor is its ability to accurately simulate the traffic-related stresses that a road pavement would undergo over its lifespan. By subjecting the asphalt mixture to repeated gyratory compaction cycles, engineers can evaluate the performance characteristics and durability of the pavement under different traffic loads. This enables them to design and construct roads that can withstand heavy traffic volumes and adverse weather conditions, reducing the need for frequent repairs and maintenance.

Proper Operation and Maintenance of the Gyratory Compactor

Proper operation and maintenance of the Gyratory Compactor is crucial to ensure its optimal performance and longevity. TheGyratory Compactor is a key equipment used in the construction industry for compacting asphalt mixtures. It plays a vital role in determining the quality and durability of pavements. To make the most of this equipment, it is essential to follow certain guidelines and procedures.

Firstly, before starting the operation of the Gyratory Compactor, it is important to conduct a thorough inspection of the machine. Check for any loose or damaged parts, ensure that all safety features are in place, and verify that the compactor is properly lubricated. Regular maintenance and servicing should be performed to keep the machine in excellent working condition.

During the operation, it is crucial to follow the manufacturer's instructions and guidelines. The compactor should be set to the correct speed and pressure settings as specified. This ensures that the compaction process is carried out efficiently and accurately. It is important to note that improper settings can lead to inadequate compaction, resulting in the formation of voids and reduced pavement performance.

In addition to proper operation, regular maintenance is essential for the gyratory compactor. This includes cleaning the machine after each use to prevent the buildup of debris and asphalt residue. The compactor should be inspected for any signs of wear and tear, and any damaged or worn parts should be replaced promptly. Lubrication of moving parts should be done as per the manufacturer's recommendations.

To maintain the desired compaction quality, it is important to monitor and adjust the gyratory compactor regularly. This can be done by conducting periodic density tests using cores or nuclear gauges. These tests help in evaluating the degree of compaction achieved and allow for adjustments to be made if necessary. It is important to maintain a uniform density throughout the pavement to ensure its durability and resistance to cracking.

Contact person: Ms. Toni Gu

Contact person: Ms. Toni Gu  toni_gu@tbt-scietech.com sales@tbt-scietech.com

toni_gu@tbt-scietech.com sales@tbt-scietech.com 0086-25-8472 1577 / 8472 1579 / 8472 1907

0086-25-8472 1577 / 8472 1579 / 8472 1907 Mobile / WhatsApp: 0086-138 5170 2127

Mobile / WhatsApp: 0086-138 5170 2127 0086-25-8472 2235

0086-25-8472 2235 Rm. 2903-2904 HuaXia Mansion, No. 81 ZhongShan Rd.,

Rm. 2903-2904 HuaXia Mansion, No. 81 ZhongShan Rd.,